Red Carpet Ready Stunning Formal Outfits for Women

Elegant Evening Attire: Formal Outfits for Women

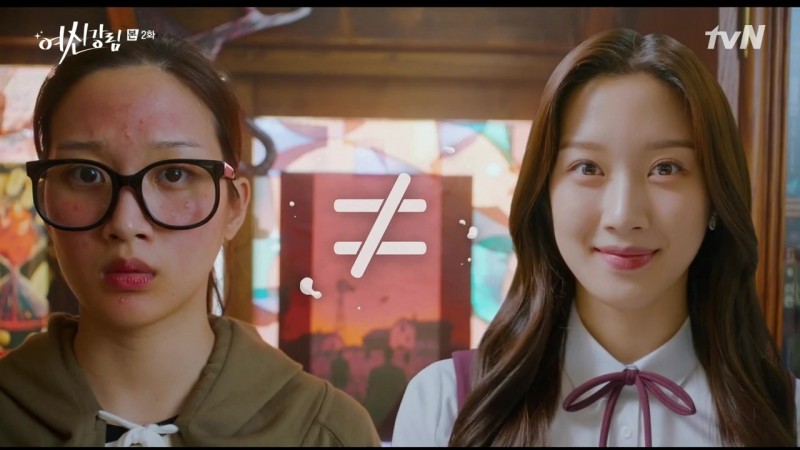

Dressing up for a formal event can be both thrilling and daunting. The excitement of finding that perfect gown or outfit is balanced with the challenge of selecting something that is not only stylish but also appropriate for the occasion. Fear not, as

:max_bytes(150000):strip_icc():focal(749x0:751x2)/carrie-bradshaw-fall-fashion-ecomm-091823-tout-0e31e74bd6a84bc4af67c076ab66c5d0.jpg)